Natural gas powers a third of the U.S. economy and accounts for 3 percent of the nation’s carbon pollution before the fuel is even burnt. But an opportunity exists to electrify natural gas that would significantly cut fugitive methane emissions, boost electric sales, and increase load flexibility.

The Massive Environmental Costs of the Other Grid

Natural gas powers about a third of the U.S. economy, from electricity to space heating to transportation. A massive grid of pipelines — about 300,000 miles of them — and 1,400 pumping or compressor stations bring the fuel from the wellhead to regional marketplaces, where the fuel can be distributed to homes and businesses.

[pullquote_left]The natural gas industry accounts for almost 3 percent of the nation’s greenhouse gas (GHG) emissions… before it is ever put to work generating electricity and heating buildings.[/pullquote_left]But this second energy grid exacts a large environmental toll. The natural gas industry accounts for almost 3 percent of the nation’s greenhouse gas (GHG) emissions, and that’s just to extract and deliver the fuel, before it is ever put to work generating electricity and heating buildings. The vast majority are so-called fugitive methane emissions — natural gas that eludes capture through leaky pipelines and inefficient equipment. Since methane has 50 to 80 times the impact as carbon dioxide, fugitives significantly amplify the industry’s environmental footprint. The single largest source of fugitive methane emissions (43%) are compressor stations, the equipment responsible for moving fuel down the pipeline.

What’s Wrong with Today’s Gas Compression?

Natural gas transmission requires compressor stations every 50 to 100 miles to keep gas flowing down the line. Compressor stations use a small amount of the gas in the pipeline to run mechanical equipment — engines and turbines — that keep the fuel flowing.

Reciprocating natural gas compressors like the one above leak significant amounts of uncombusted methane into the atmosphere. As a GHG, methane is 50 to 80 times as potent as CO2.

A single station could contain several large compressors, each rated at thousands of horsepower.

Gas-fired stations have several significant downsides. Aside from being relatively inefficient, the equipment used in pipeline compression also “slips” significant amounts of natural gas, meaning that uncombusted gas passes through the equipment directly into exhaust. Gas-fired compression equipment also emits nitrous oxides (NOx), which contribute to local air pollution and factor into air permit requirements. Finally, gas-fired compression equipment requires significant, costly maintenance.

The Opportunity: Electrify Natural Gas

[pullquote_right]Electrification of gas compression would eliminate about 70 million metric tons CO2e in GHG emissions per year, over 1 percent of the nation’s overall GHG emissions and larger than the GHG impact of many states.[/pullquote_right]A switch to electric compression can effectively eliminate fugitive methane emissions from compressor stations, reduce NOx air pollution (relaxing air permitting constraints), and reduce maintenance costs as well. However, pipelines are mission-critical pieces of the nation’s energy infrastructure, so any electric compression needs to be secured with backup power (diesel generators, for example) in the event of grid outages. Fortunately, new hybrid or dual-fuel compressor technologies allow stations to run on electricity the vast majority of the time, switching back to natural gas in emergency situations or when the local grid requires additional capacity. This means that compressors can capture the environmental benefits of electric compression, maintain a secure source of power, and provide grid services as an added source of revenue.

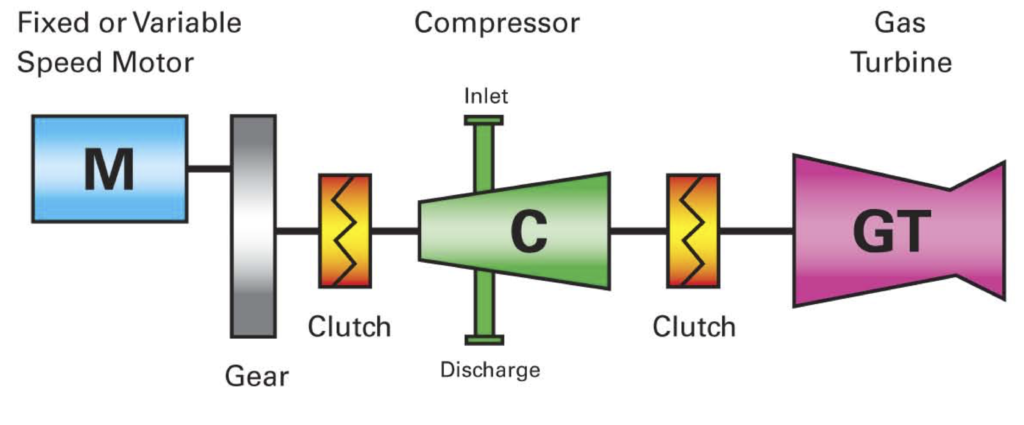

Dual-fuel compressors move gas with electric motors most of the time, but fall back on gas-fired compression as needed based on grid conditions.

All told, electrification of gas compression could provide significant environmental and cost benefits. We estimate that nationwide electrification of gas compression would eliminate about 70 million metric tons CO2e in GHG emissions per year, over 1 percent of the nation’s overall GHG emissions and larger than the GHG impact of many states. It would also generate over $3 billion in additional electricity sales for utilities, all delivered to large, stable loads with very high load factor. Furthermore, with the ability to control and curtail hybrid compressors in a grid-interactive manner, utilities could provide 12 to 15 gigawatts of demand flexibility.

The greatest opportunities for gas pipeline electrification, naturally, occur in states with heavy oil and gas development, such as Texas, Louisiana, and Pennsylvania (see map below), but nearly every state in the lower 48 has some amount of compressor station electrification potential. Electrifying natural gas is, therefore, an opportunity for most electric utilities.

Where to Electrify Natural Gas

Where can utilities begin to understand this large opportunity? Xergy has developed interactive tools to help utilities explore opportunities to electrify natural gas compressors in their service territories. Utilities can drill down to specific compressor installations, analyze the size of the opportunity, and identify the pipeline operator (Note: our publicly available maps only include compressor stations on interstate pipelines). Visit www.xergyconsulting.com/electrify-ng to explore for yourself!